DESIGN.

BUILD.

TEST.

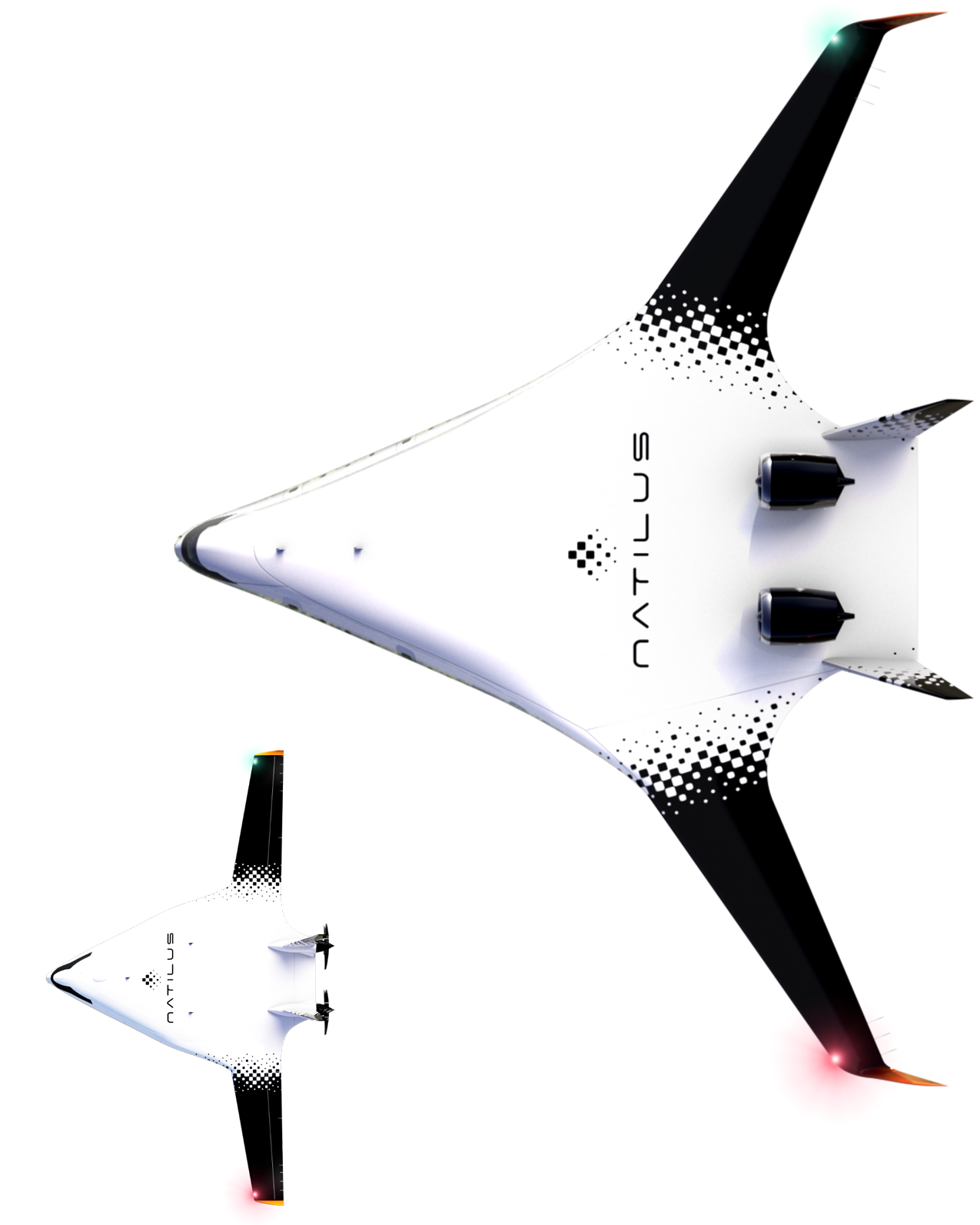

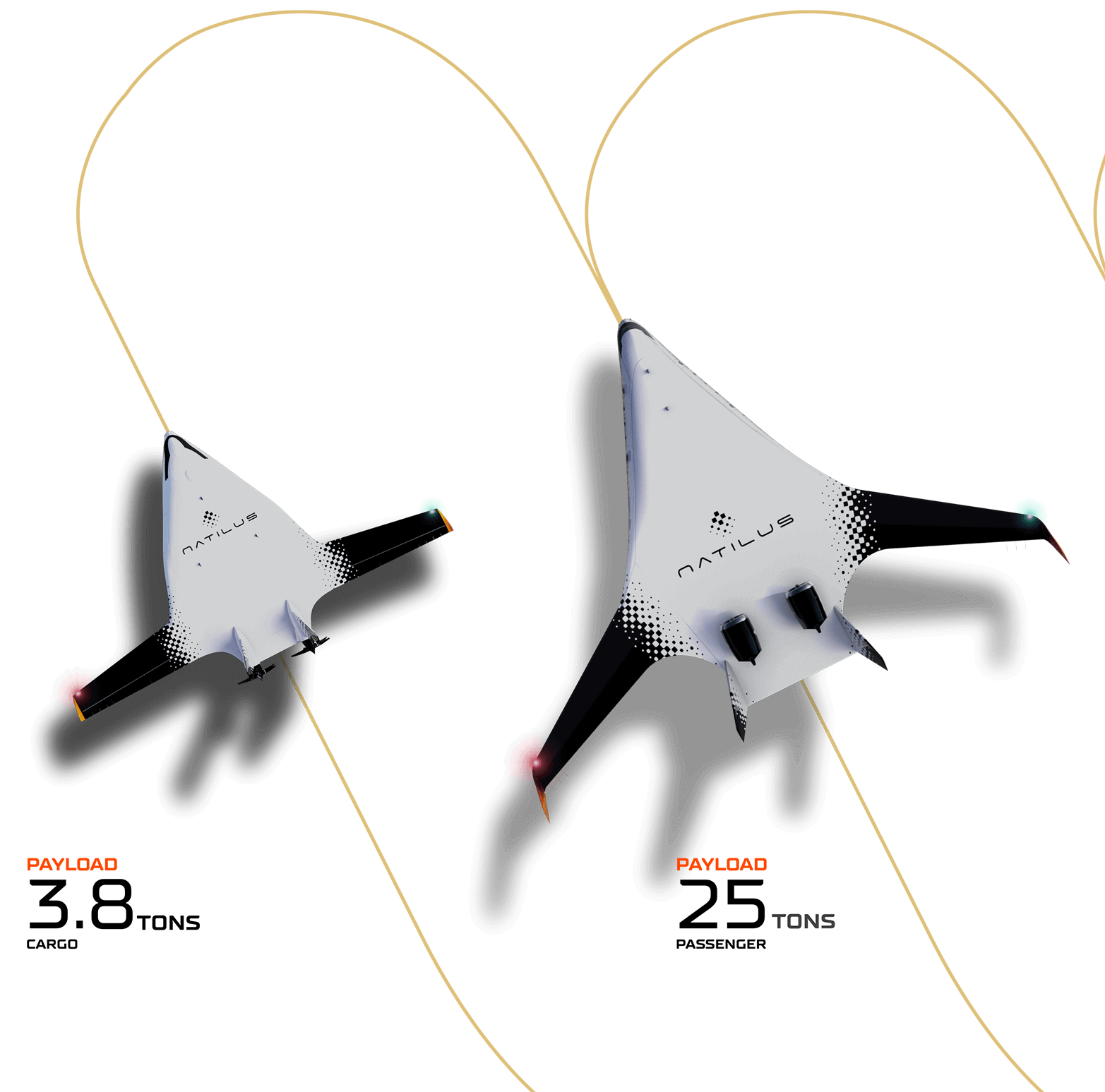

With improved fuel efficiency and the room to accommodate future propulsion technologies, BWB aircraft can significantly reduce greenhouse gas emissions, addressing environmental concerns in aviation.